Our Services

Pro-Q commits to maintain high level of quality standard operation, all inspectors are qualified for different type of inspection with regular training by experiences manager.

Our services policy

As you trusty with Pro-Q as a 3rd party of sorting, inspection and logistics resolution service, we go into action following:

- We inspect non-conforming or suspect parts based on customer clearly specification or criteria and procedures.

- We rework each non-conforming parts followed instruction and re-inspects before accepting it as good.

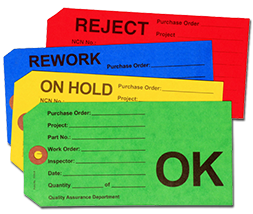

- We separate and mark each inspected part as conforming or non-conforming part.

- We quarantine the non-conforming or rejected parts and place in right location.

- We deliver a site report to the customer personal with sufficient information before we leaves site.

- We keep you informed as the work is done. Visitation reports are sent to the customer after each work, or each day's activity.

Our core services

We have a variety of services to ensure that non-conforming part or suspect materials are inspected, packaging and labeling issue dealt with in the most appropriate manner, this including:

Sorting

Pro-Q employs qualified personnel to sort specified lots of non-conforming or discrepant parts following the agree operation instruction in order to ensure that absolutely no defect parts escape to production lines.

De-rusting

The ferrous material sometime occurs with rust when use in difference environmental, we helps to complete removal of rust from your parts using a de-rust agent and applying a protective anti-rust coating to the part for short term. We also can de-rust without grinding or power tools. That means no surface damage, tolerances are held to the original state of the part and no flash rusting occurs. Most importantly, less labor equals less cost for you.

Reworking / Repairing

Not all non-conforming or rejected part needs to be thrown in the recycling bin, Sometimes a non-conforming part i.e. Burrs, partially filled holes, improper installations can be used if it is modified or reworked. Pro-Q will work with you to rework the identified part to your documented specifications. This can help save time and money.

3rd party inspection

Pro-Q is 3rd party Inspection resources that can help you deal with quality issues quickly. Parts can be inspected per agree specification at your location, or diverted from your facility to external warehouse for inspection before they are delivered customer to enhance the level of satisfaction are met.

Repacking and labeling

Packaging can sometimes be interrupt the manufacturing process or shipment planed. Pro-Q, we can help by rechecking the packaging materials and correct to right packaging, labeling standard with right location, you can have predictable costs ,most convenient and claim to right responsible party, and we can also work with you to find alternatives to manual packaging boxes.

Packaging management

Packaging can also treat as part or machine for manufacturing, assume that the production team did well to build the products as customer demand, but no packaging available or packaging are damage and not ready for use, this can be costed to business and risk to reduce customer satisfaction. Pro-Q can assist you to providing with resource to perform the cycle counts on packaging to ensure that the physical packaging are correct and accuracy and we can also performing the packaging maintenance to obtain the proper condition of use.

Incoming and control shipment (CS1,CS2)

Controlled shipment also known as restricted shipment, is a process applied when a normal inspection processes not sufficient to protect the customer from non-conforming part, the supplier is required to immediately put in place the additional inspection process to sort for non-conforming part/material by 3rd party company inspection while implementing a root cause of problem solving, Pro-Q is independent source of inspection services which capability off-line inspects the products and capable to produce the check sheet with I chart throughout the step of existing criteria of control shipping.

Launch support and GP12 early production

We understand the market specification in Automotive that products on early of production phase need to be closed monitor on processes and product performance, sometime your need someone present at customer location to observe the assembly process then get feedback to business for further improvement or your customer required purchasing contractual of the early production containment procedure ,is an extra inspection process for some specific period to validation process and ensuring the variation is under control and met the exist criteria, Pro-Q can be provided the resident inspector or quality supervisor to support this with data collection and site report regularly.

Quality concern, process and system verification

As we experience and understand on how you concern on effectiveness of corrective and preventive action in supply chain when you are on difficult time to make trips to see what exactly happening in place to fix your problem, ask Pro-Q to assist you where we able to provide the onsite validation with objective evident back to you .This can be saved your travelling cost and mostly save your time.

Supplier Evaluation, Factory evaluation, Factory Audit

As you know the organizations handle with so many suppliers in different location for any activities through the products life cycle, the supplier involvement is conducting from new supplier selection to the regular audits of existing suppliers to ensuring that supplier can fulfill the order within the deadline and meet your quality requirement level.

Our service of Supplier Evaluation, Factory evaluation, Factory audit will help you to improve work and cost efficiency perspective. We can help you make your crucial decision on whether you should trust and move forward with a potential supplier or maintain the business or switch off with them, A factory audit (factory evaluation, supplier evaluation) report with full information will be emailed to you within 24 hours. By our audit report package, you will have a general understanding to the supplier and basic feeling or ranking score if they are reliable to do business with.

The mandatory item below it will be carrying out during an audit

⦁ Surveying the factory profile such as organization structure, certifications, personnel, equipments and facilities etc.

⦁ Assessing production processes, production capacity, engineering capability and relative resources.

⦁ Checking quality assurance and process control system and quality management system.

⦁ Checking previous production records and current customer statistician level.

⦁ Taking pictures with necessary objective evident into audit report package,

so every aspect so you can get the "feeling" of the factory.

Your benefits of using our factory audit (factory evaluation, supplier evaluation) service:

⦁ Through our factory evaluation, Get the "feeling" of the factory without being on-the-spot.

(Save your time, save your money)

⦁ Make your crucial decision on whether you should trust and move forward with

a potential Thailand supplier after reading our factory audit report.

⦁ Improve the sourcing and supplier management efficiency.